Address

Studio 03

SUM Studios

1 Hartley Street

Sheffield

S2 3AQ

[email protected]

0114 399 1023

Prefabrication and off-site manufacturing promise speed, efficiency, and cost control. But those benefits only materialise when designs are based on accurate, real-world conditions. When assumptions replace reality, projects face clashes, delays, and wasted fabrication runs.

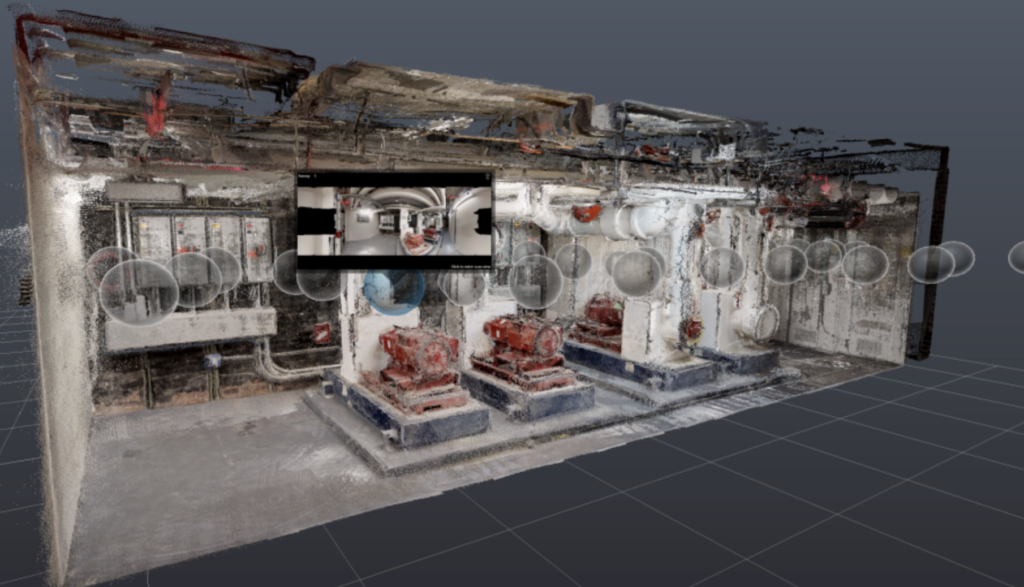

This is where point clouds play a critical role. By capturing the precise geometry of existing conditions, point clouds remove uncertainty and allow prefab elements to be designed and manufactured with confidence.

A point cloud is a highly detailed digital representation of a physical space, created using laser scanning or advanced photogrammetry. Millions of measured points capture exact geometry, including walls, floors, ceilings, structural elements, and services.

Unlike traditional surveys or 2D drawings, point clouds reflect what actually exists on site, not what was assumed or documented years ago.

Prefab components are manufactured before arriving on site. That means there is very little tolerance for error.

If a beam is even a few millimetres out, or a service route clashes with existing structure, the result is often rework, site delays, or complete remanufacture. These issues can quickly wipe out the cost savings that prefab is meant to deliver.

Accurate geometry is the foundation that makes prefab viable.

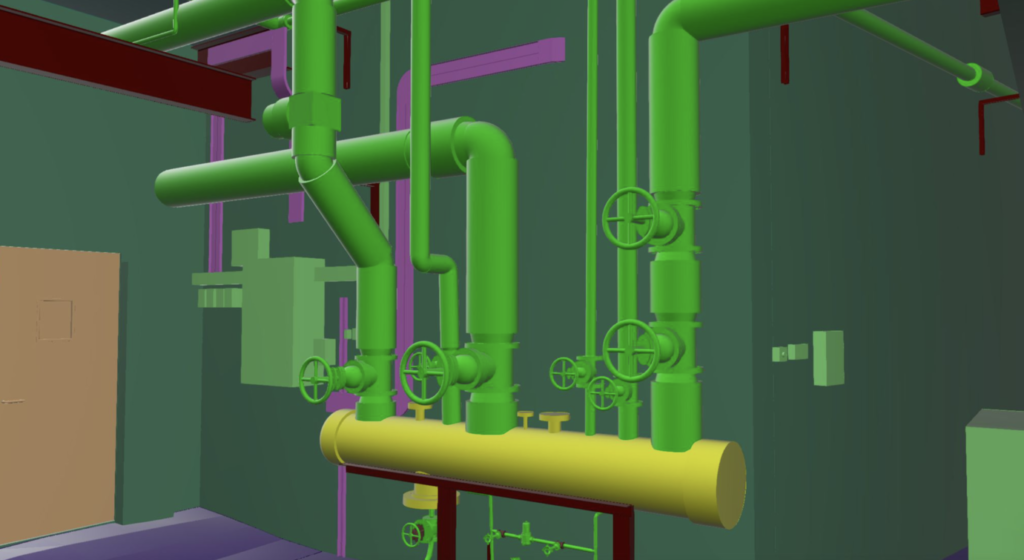

Point clouds give project teams a reliable starting point. Designers, engineers, and manufacturers can work from the same source of truth.

This accuracy helps to:

By designing directly against real conditions, the risk of expensive surprises on site is dramatically reduced.

One of the biggest causes of wasted fabrication runs is geometric clashes. These often occur when prefabricated elements are designed using incomplete or inaccurate information.

Point clouds allow teams to:

This shifts problem-solving from site to design, where changes are faster, cheaper, and far less disruptive.

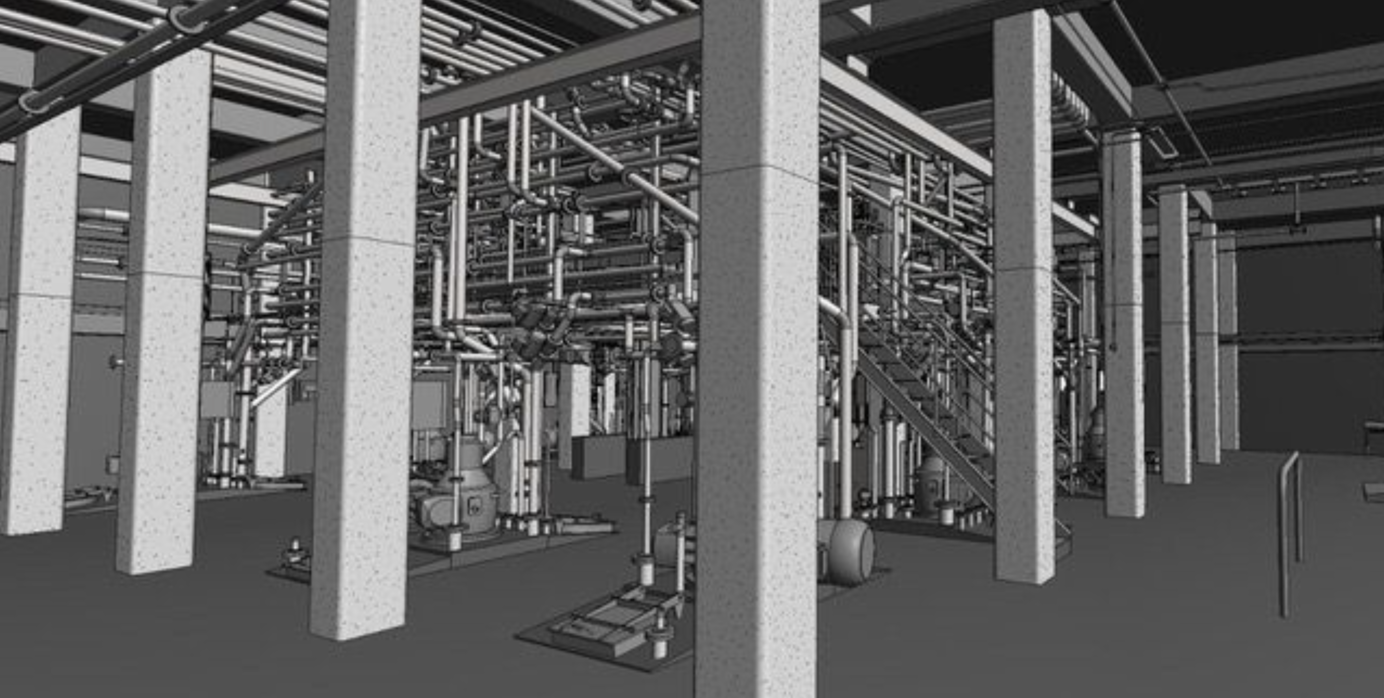

Point clouds integrate seamlessly with BIM and CAD workflows. Designers can convert scan data into accurate models or use the point cloud directly as a reference.

This enables:

When geometry is correct from the start, manufacturing becomes predictable instead of reactive.

Off-site manufacturing is meant to reduce time spent on site. However, when prefab elements do not fit as expected, installation teams are forced into last-minute fixes.

Using point clouds helps ensure:

This leads to smoother programmes and fewer delays caused by unforeseen spatial issues.

Prefab is increasingly used in retrofit and refurbishment projects, where existing conditions are rarely straightforward. Older buildings often differ significantly from their original drawings.

Point clouds capture these irregularities in full detail, allowing prefab solutions to be designed around real constraints rather than idealised layouts. This is especially valuable for structural upgrades, MEP prefabrication, and modular or façade components.

Accurate geometry is the difference between a prefab that works and a prefab that fails. With point cloud data, teams can design, fabricate, and install with confidence, avoiding costly clashes and wasted fabrication runs.Scene3D provides high-accuracy point cloud surveys, enabling more innovative off-site manufacturing and more reliable project outcomes. If you want to reduce risk, improve coordination, and ensure your prefab components fit the first time, now is the time to start with reality.